In today’s rapidly evolving automotive industry, electric vehicles (EVs) are truly emerging as the future of transportation. And we, as OEM/ODM suppliers of PCB and PCBA assembly services, play a crucial role in ensuring the seamless operation of battery storage PCBA BMS for electric vehicles.

The electric vehicle revolution is being driven by several factors. There’s the growing concern over environmental sustainability, which prompts more and more people to look for greener transportation options. Government incentives also play a significant part, making EVs more accessible and appealing. And of course, advancements in battery technology are constantly pushing the boundaries of what’s possible. As more consumers switch to electric vehicles, we understand that the need for high-performance battery systems is becoming increasingly important. These systems must provide longer ranges, faster charging times, and enhanced safety. This is where our expertise comes into play.

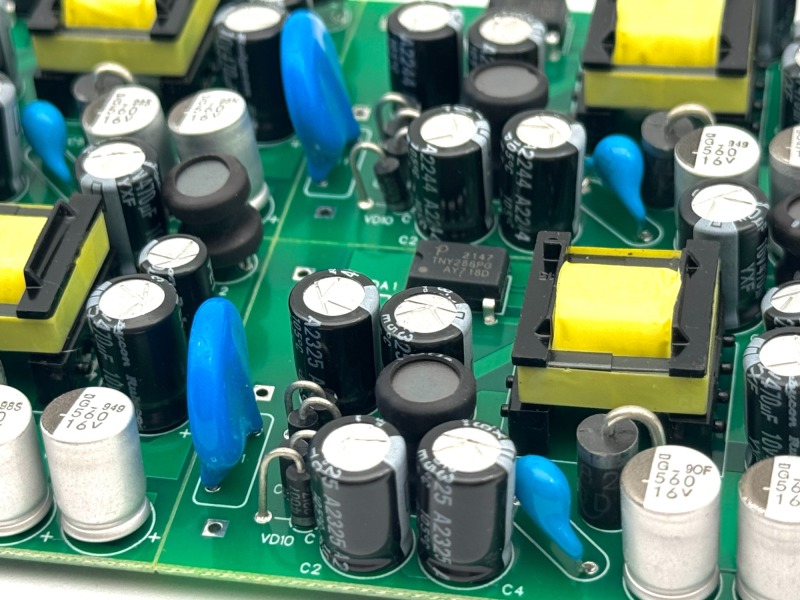

We offer a wide range of services. From PCB design to manufacturing, and from PCBA assembly to testing, we are committed to providing end-to-end solutions. As reliable pcba suppliers, we take pride in our ability to handle every aspect of the production process. In the design phase, we use advanced software tools and simulation techniques to create optimized PCB layouts. When it comes to BMS pcba design, we carefully consider factors like electrical performance, thermal management, and signal integrity. This ensures that the PCBA we design is not only functional but also highly reliable and durable.

Once the design is finalized, our manufacturing process kicks in. We use state-of-the-art manufacturing equipment and processes to produce high-quality PCBs. We source only the best materials from trusted suppliers to guarantee that our finished products meet or exceed industry standards.

After manufacturing, the PCBA assembly process begins. We have highly trained technicians and automated assembly lines that can handle large volumes of production with precision and efficiency. Whether it’s surface mount technology (SMT) or through-hole technology (THT), we choose the right method based on the specific requirements of the application.

Quality control is a top priority for us. We employ a variety of testing and inspection methods to ensure that every PCBA is of the highest quality. Electrical testing, functional testing, and visual inspection are all part of our rigorous quality control process. This way, we can detect any defects or issues that might affect the performance of the battery storage PCBA BMS.

In addition to manufacturing and assembly services, we also offer value-added services such as product engineering, prototyping, and supply chain management. We help electric vehicle manufacturers optimize their product designs, reduce costs, and improve time-to-market.

The battery storage PCBA BMS for electric vehicles is a complex system that demands advanced technology and expertise. As pcba suppliers, we are dedicated to meeting these challenges. We stay at the forefront of technological innovation and continuously improve our services to keep up with the dynamic market. This might involve investing in research and development, adopting new manufacturing technologies, and expanding our capabilities to handle larger volumes of production.

In conclusion, we, the OEM/ODM suppliers of PCB and PCBA assembly services, are essential partners for electric vehicle manufacturers. Our expertise in battery storage PCBA BMS design and manufacturing can help drive the growth of the electric vehicle industry. As the electric vehicle revolution continues, we will remain committed to providing reliable, efficient, and cost-effective solutions. Together, we can shape the future of transportation.

Post time: Dec-05-2024