With the popularization of intelligent TV and the miniaturization of devices, PCB boards are developing towards a more compact line spacing and smaller via. However, such motherboards are prone to problems in the high temperature and high humidity environment, which has always been an obstacle to service work. The faulty boards and the newly requisitioned core boards can be operated according to this method. In order to avoid future failures of the newly requisitioned boards, it is recommended to do moisture-proof treatment in advance. In order to better protect the circuit board, manufacturers will conduct surface moistureproof treatment on the circuit board when assembling electronic products. At this time, HN201 shallow potting adhesive for circuit board of Good Viscose Industry will play a role. This adhesive is a one component, low viscosity, dealcoholized room temperature curing organic silicon shallow potting adhesive. It emits low molecules through condensation reaction of water in the air to cause cross-linking and curing, and vulcanizes into high-performance elastomer.

Widely used in household appliances, chargers electronic equipment, LED lighting, instruments and meters, mechanical equipment, communication cables, automobile and motorcycle industry, solar photovoltaic, aerospace and other industries; Such as: LED module encapsulation, waterproof and moisture-proof of photoelectric displays, electronic components, electrical modules and circuit boards, moisture-proof and waterproof encapsulation of electronic accessories, insulation and coating protection of various circuit boards, bonding and shallow encapsulation of various optical instruments, chemical equipment, mirrors, electrical and communication equipment, underwater instruments, electronic and electrical sensors, small household appliances, etc., elastic bonding of metal and non-metallic materials.

After the nano waterproof coating is sprayed on the electronic circuit board and dried, a transparent colorless molecular waterproof membrane chain can be formed in the water and normally attached to the protection component, so that the water cannot contact the protection component. Not only waterproof, but also resistant to acid and alkali, corrosion, and will not affect the clarity of optical lenses. In addition, due to the invisible molecular film coating technology, its coating thickness reaches nanometer level, which will not affect the use of connectors. Therefore, it can directly carry out waterproof treatment for mobile phone motherboards.

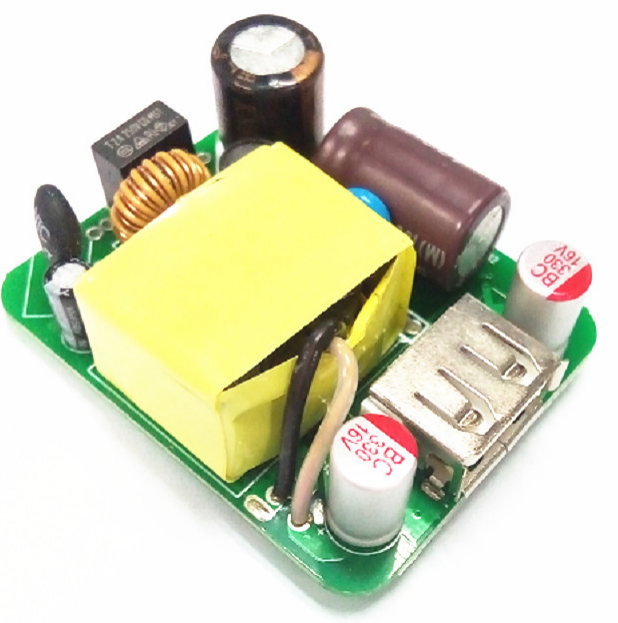

APS focuses on designing and manufacturing of all kinds Power supply adapters including wall charger car charger,PD charger wireless charger and portable charger. With more than 12 years OEM&ODM factory experiences, we can flexibly meet the diverse needs of different clients all over the world and their pursuit of high-speed innovation.APS owns the core technology and intellectual property rights of its independent products, and works tirelessly to innovate, improve, and continually optimize.

Post time: Nov-29-2022